NEWS

2024/08/15

What are Vacuum Components?

What are Vacuum Components?

Vacuum components are essential elements in vacuum systems, responsible for creating, maintaining, and controlling a vacuum environment. These components play a crucial role in various industries, including food processing, pharmaceuticals, electronics, and semiconductor manufacturing.

Where Are Vacuum Components Typically Used in Semiconductor Manufacturing?

In semiconductor manufacturing, vacuum components play a crucial role in several key processes:

- Etching: Vacuum chambers are used for precise material removal.

- Deposition: Thin films are applied under vacuum conditions to ensure uniformity and quality.

- Packaging: Semiconductor devices are sealed in a vacuum to prevent contamination.

- Handling: Wafers are transported through vacuum systems to avoid contamination.

What Are the Different Types of Vacuum Components?

- Vacuum Pumps: Devices that create and maintain a vacuum by removing air and gases.

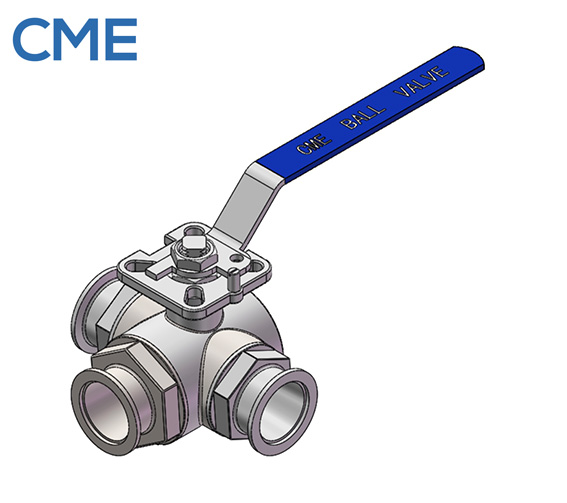

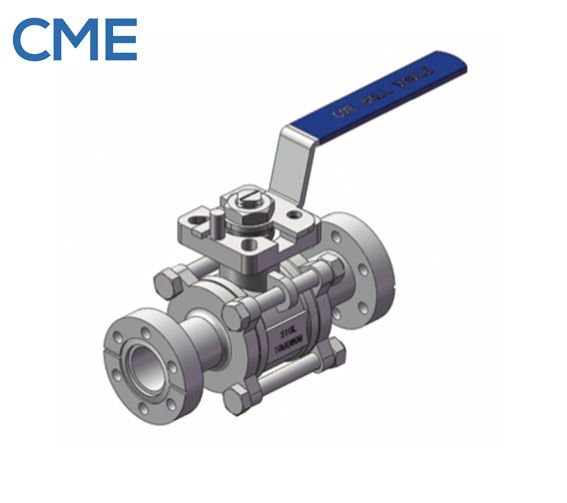

- Vacuum Valves: Components that control the flow of gases or fluids within vacuum systems.

- Vacuum Gauges: Instruments used to measure vacuum pressure accurately.

- Vacuum Chambers: Enclosed spaces designed for conducting vacuum processes.

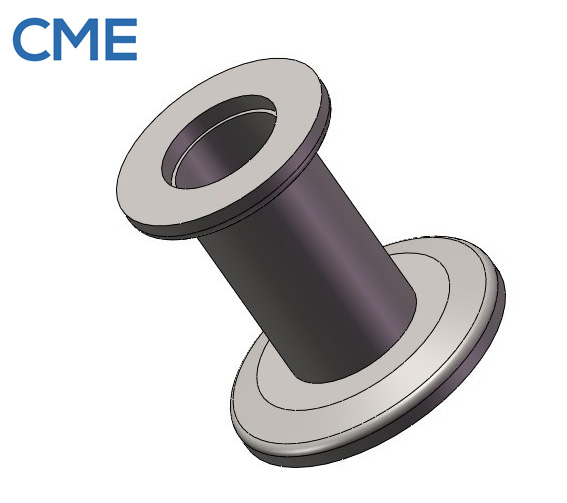

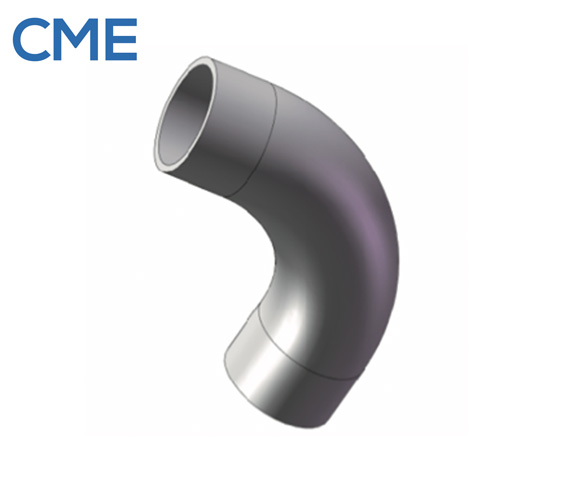

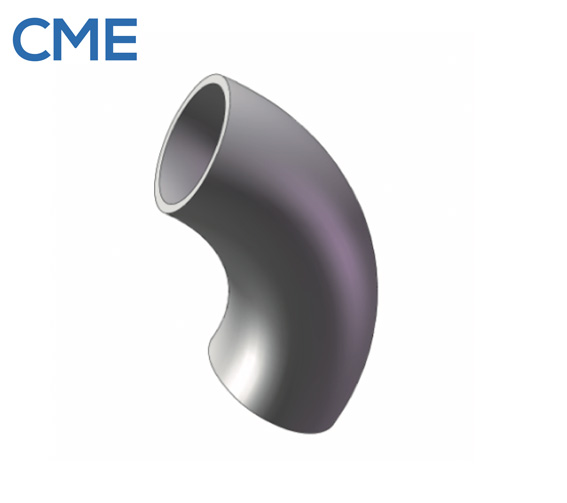

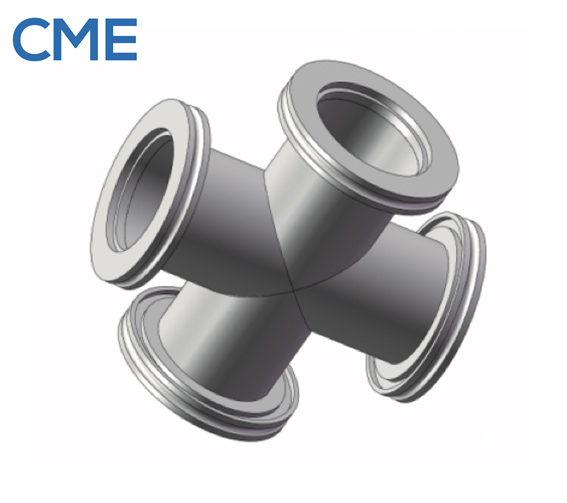

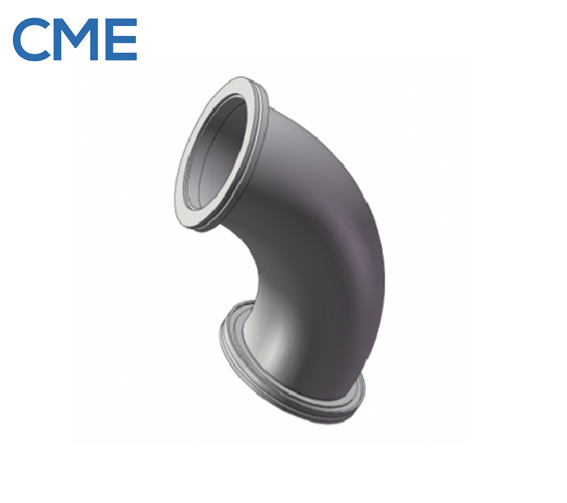

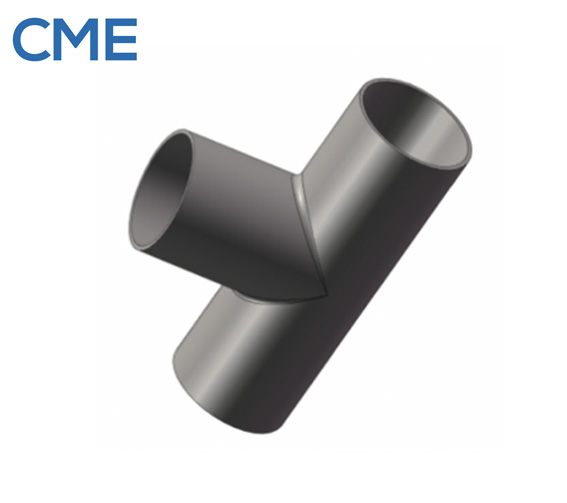

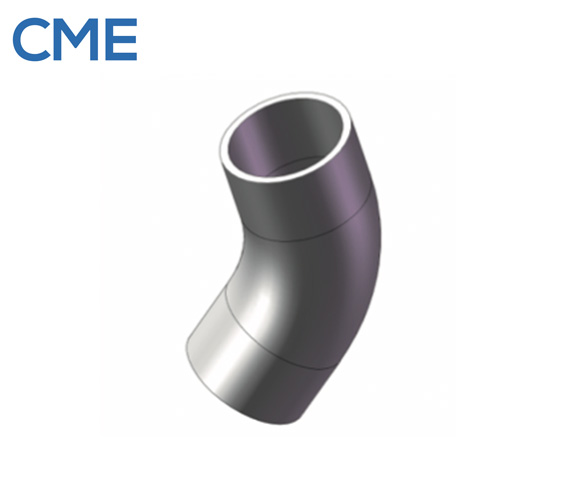

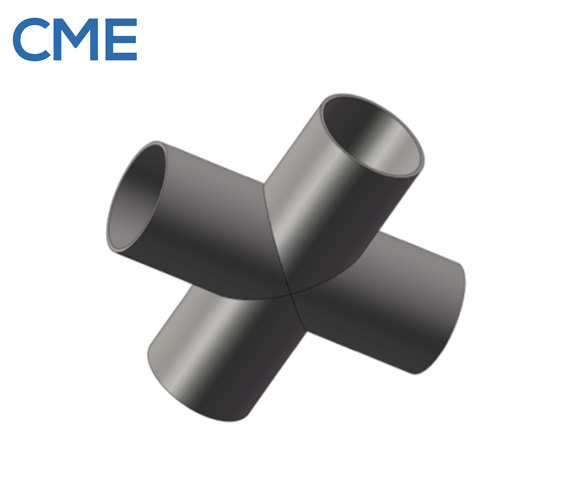

- Vacuum Tubing and Fittings: Connect components to ensure seamless gas flow throughout the system.

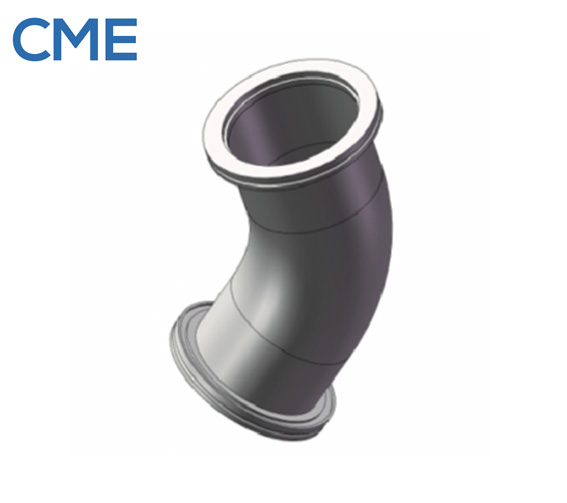

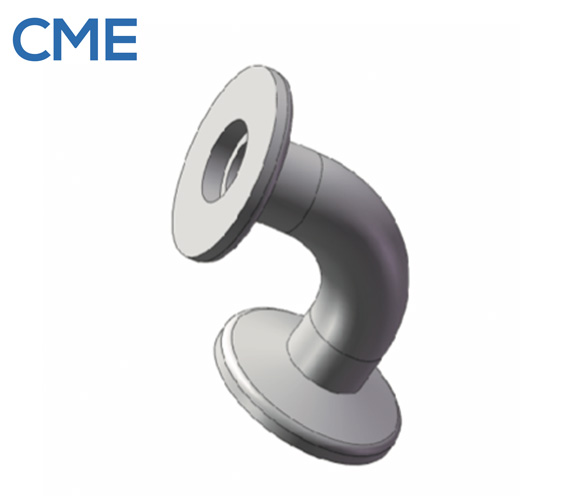

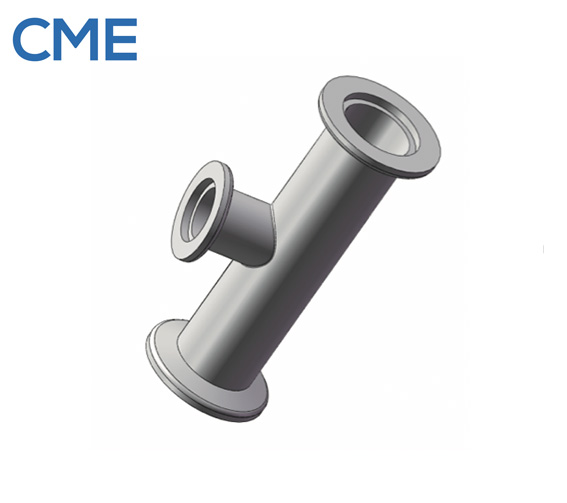

- Flanges and Fittings: Provide secure and leak-proof connections between vacuum components.

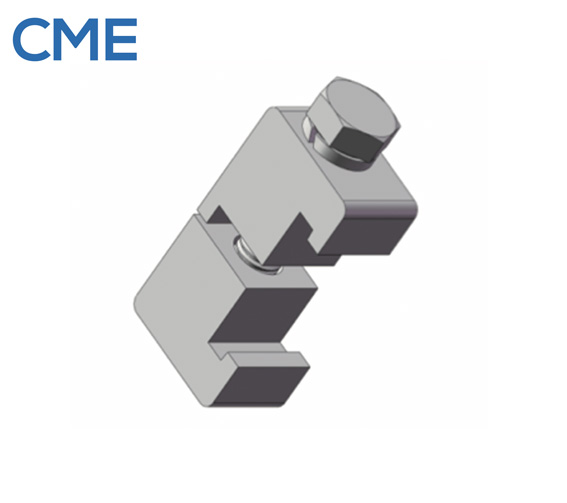

- Vacuum Clamps and Claws: Ensure tight seals and secure connections in vacuum systems.

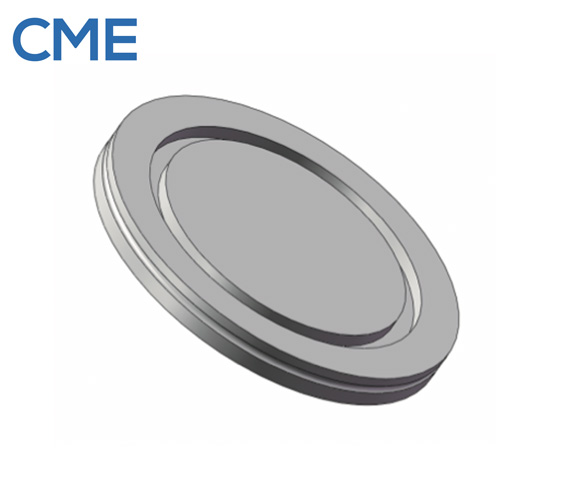

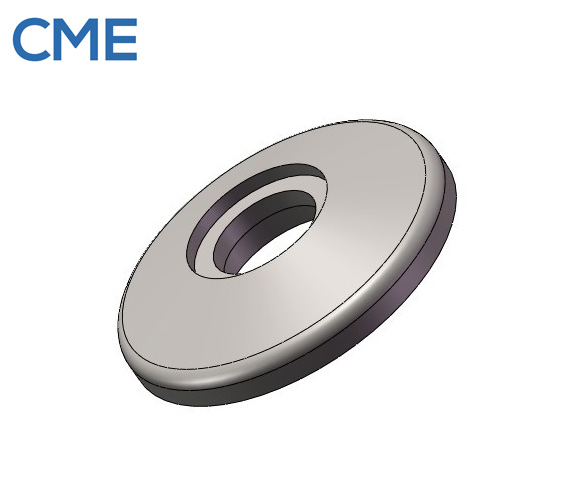

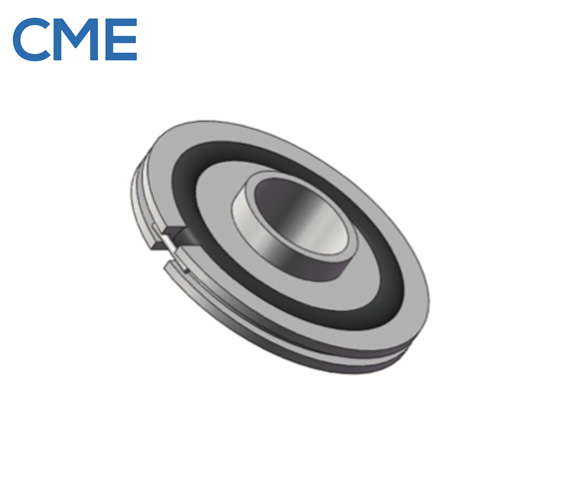

- Center Rings: Assist in creating secure, leak-free connections between components.

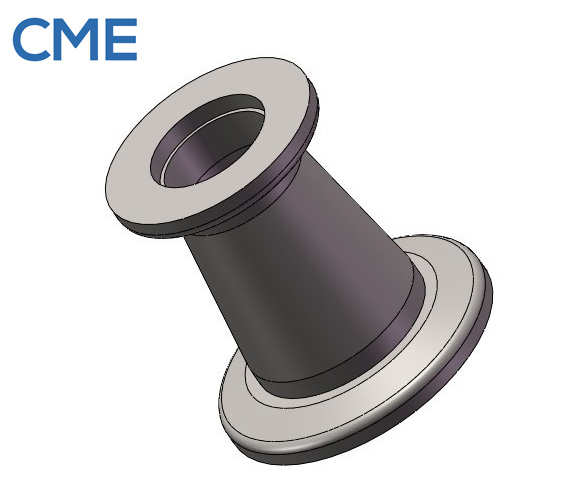

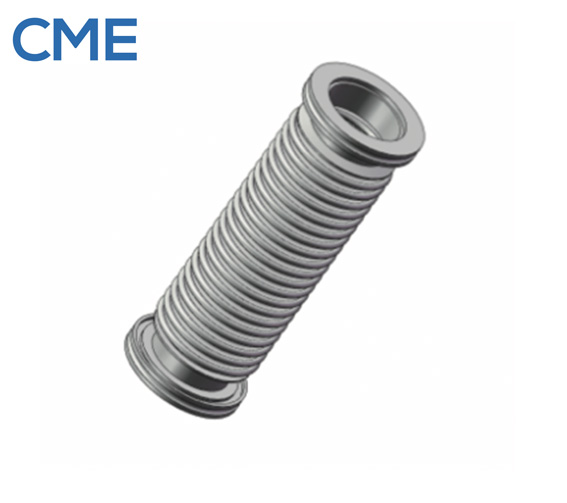

- Vacuum Bellows and Flexible Hoses: Allow flexibility and movement within vacuum systems.

Key Considerations for Selecting Vacuum Components for Semiconductor Manufacturing

- Material Compatibility: Select high-purity, corrosion-resistant materials to ensure longevity and reliability.

- Performance Requirements: Ensure components meet the necessary vacuum levels and flow rates specific to your application.

- Cleanliness: Choose components that are easy to clean, maintaining the integrity of the manufacturing process.

- Compliance with Standards: Adhere to industry standards to ensure compatibility and safety.

- Compatibility with Existing Equipment: Ensure seamless integration with current systems to avoid operational disruptions.

- Supplier Reputation and Support: Choose reputable suppliers known for quality products and reliable customer support.

About CME

CME is a trusted provider of high-quality vacuum components, specifically designed to meet the stringent requirements of the semiconductor industry. Our precision-engineered products ensure optimal performance and full compliance with industry standards. Visit our website to learn more. information:(https://www.cmevalves.com/products_category.aspx?id=9).

RELATED PRODUCTS